Why Preventive Maintenance Is Key for Fleet Longevity sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with casual formal language style and brimming with originality from the outset.

The content of the second paragraph that provides descriptive and clear information about the topic

Importance of Preventive Maintenance

Preventive maintenance is crucial for ensuring the longevity of fleet vehicles. By conducting regular maintenance checks and addressing issues proactively, fleet managers can avoid costly breakdowns and repairs, ultimately saving time and money in the long run.

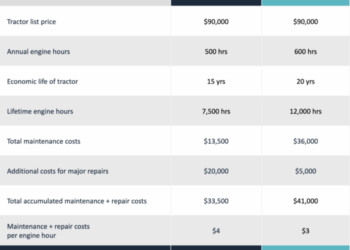

Cost Savings through Preventive Maintenance

Implementing a preventive maintenance program can lead to significant cost savings for fleet operations. By identifying and addressing minor issues before they escalate into major problems, companies can avoid expensive repairs and minimize downtime. Regular maintenance also helps improve fuel efficiency and prolong the lifespan of vehicles, reducing the need for premature replacements.

Impact of Neglecting Preventive Maintenance

Neglecting preventive maintenance can have serious consequences on fleet performance. Without regular inspections and servicing, vehicles are more prone to unexpected breakdowns, leading to costly repairs, delays in deliveries, and potential safety hazards for drivers and other road users. Ignoring maintenance schedules can also result in decreased fuel efficiency, reduced productivity, and overall higher operational costs.

Components of Preventive Maintenance

Preventive maintenance is crucial for ensuring the longevity and efficiency of fleet vehicles. A comprehensive preventive maintenance plan should include several key components to keep the fleet running smoothly and minimize the risk of unexpected breakdowns.

Regular Inspections and Servicing

Regular inspections and servicing play a vital role in preventive maintenance. By conducting routine checks on various components of the vehicles, such as brakes, tires, fluids, and filters, potential issues can be identified and addressed before they escalate into more significant problems.

This proactive approach helps in maintaining the optimal performance of the fleet and ensures the safety of drivers and passengers.

- Inspecting brake systems to ensure they are functioning properly and replacing worn-out brake pads to prevent brake failure.

- Checking tire pressure and tread depth regularly to avoid blowouts and improve fuel efficiency.

- Changing oil and filters at recommended intervals to keep the engine running smoothly and prevent overheating.

Scheduled Maintenance Tasks

Scheduling maintenance tasks at regular intervals is another essential component of preventive maintenance. By setting up a maintenance schedule based on manufacturer recommendations and the specific needs of the fleet, potential issues can be identified early on and addressed before they lead to breakdowns or costly repairs.

Regular maintenance also helps in extending the lifespan of the vehicles and maintaining their resale value.

Preventive maintenance is not just about fixing things when they break; it's about preventing things from breaking in the first place.

- Creating a maintenance calendar to track upcoming service intervals for each vehicle in the fleet.

- Scheduling routine inspections and servicing during downtimes to minimize disruptions to operations.

- Keeping detailed records of maintenance activities and repairs to track the performance of each vehicle and identify any recurring issues.

Benefits of Preventive Maintenance

Implementing a proactive maintenance approach can bring numerous advantages to a fleet operation

Improved Fleet Safety

- Regular inspections and maintenance checks help identify potential issues before they become safety hazards on the road.

- Well-maintained vehicles are less likely to experience breakdowns or malfunctions that could lead to accidents.

- Ensuring that all components are in optimal condition can contribute to better overall vehicle performance and driver safety.

Extended Fleet Lifespan

- Fleets that undergo preventive maintenance on a regular basis tend to have longer lifespans compared to those that receive sporadic or reactive maintenance.

- Proactively addressing wear and tear on vehicles can prevent costly repairs and unexpected downtime, ultimately extending the operational life of the fleet.

- Regular maintenance can also help maintain the resale value of fleet vehicles by ensuring they are in good condition and well-maintained.

Best Practices for Implementing Preventive Maintenance

Preventive maintenance is crucial for ensuring the longevity of your fleet vehicles. By following best practices, fleet managers can effectively implement preventive maintenance programs that can help reduce downtime, increase efficiency, and ultimately save costs in the long run.

Designing a Preventive Maintenance Checklist

To ensure that all aspects of your fleet vehicles are properly maintained, it is essential to design a comprehensive preventive maintenance checklist. This checklist should include regular inspection of key components such as brakes, tires, fluids, and engine performance. By systematically checking and maintaining these components, you can prevent unexpected breakdowns and extend the lifespan of your vehicles.

Organizing an Effective Preventive Maintenance Program

Developing an effective preventive maintenance program involves setting clear guidelines and procedures for routine inspections and maintenance tasks. Start by creating a schedule for regular maintenance checks based on vehicle usage and manufacturer recommendations. Additionally, establish protocols for recording maintenance activities, tracking vehicle history, and addressing any identified issues promptly.

By organizing a structured preventive maintenance program, fleet managers can ensure that all vehicles receive timely and consistent maintenance, leading to improved reliability and performance.

Creating a Timeline for Routine Maintenance Tasks

To maintain fleet longevity, it is essential to establish a timeline for conducting routine maintenance tasks. This timeline should Artikel specific intervals for oil changes, filter replacements, tire rotations, and other essential maintenance activities. By adhering to a predetermined schedule, fleet managers can proactively address maintenance needs before they escalate into more significant problems.

Regular maintenance not only helps extend the lifespan of fleet vehicles but also contributes to better fuel efficiency, reduced emissions, and overall cost savings.

Wrap-Up

The content of the concluding paragraph that provides a summary and last thoughts in an engaging manner

Clarifying Questions

Why is preventive maintenance important for fleet longevity?

Preventive maintenance helps in identifying potential issues before they escalate, ensuring the fleet operates efficiently and extends its lifespan.

What are the key components of preventive maintenance?

Key components include regular inspections, timely servicing, and scheduled maintenance tasks to prevent breakdowns.

How does preventive maintenance save costs in the long run?

By addressing issues early on, preventive maintenance prevents major breakdowns that can be more costly to repair.

What are the benefits of implementing a proactive maintenance approach?

A proactive approach enhances fleet safety, reduces downtime, and increases overall efficiency.

What are the best practices for implementing preventive maintenance?

Best practices include designing a checklist, creating a maintenance program, and scheduling routine tasks effectively.