Embark on a journey through the world of fleet maintenance costs with the 2025 Edition. Delve into the intricacies of comparing expenses, exploring trends, and understanding key factors that shape the landscape of fleet management.

Introduction to Fleet Maintenance Cost Comparison: 2025 Edition

As we dive into the 2025 edition of Fleet Maintenance Cost Comparison, it becomes crucial for fleet managers and operators to understand the significance of comparing maintenance costs in the current year. This analysis provides valuable insights into optimizing operational expenses, enhancing efficiency, and maximizing the lifespan of fleet vehicles.

Key Factors Influencing Fleet Maintenance Costs

Several factors play a pivotal role in determining the maintenance costs of a fleet. These include:

- Vehicle Age and Mileage: Older vehicles tend to require more frequent and costly repairs compared to newer ones.

- Maintenance Schedule Adherence: Following a strict maintenance schedule can prevent unexpected breakdowns and reduce long-term expenses.

- Quality of Parts and Service: Opting for high-quality parts and services can impact the overall maintenance costs over time.

- Driver Behavior: Safe driving practices can contribute to lower wear and tear on vehicles, ultimately reducing maintenance needs.

Significance of Staying Updated with Cost Comparisons for Fleet Management

Regularly updating and comparing fleet maintenance costs is essential for effective fleet management due to the following reasons:

- Cost Optimization: Identifying cost-saving opportunities and implementing efficient maintenance strategies can lead to significant savings.

- Performance Monitoring: Comparing costs allows for the tracking of maintenance trends and evaluating the effectiveness of current maintenance practices.

- Budget Planning: Accurate cost comparisons aid in budget forecasting and allocation, ensuring financial stability within the fleet management operations.

Methodologies for Fleet Maintenance Cost Analysis

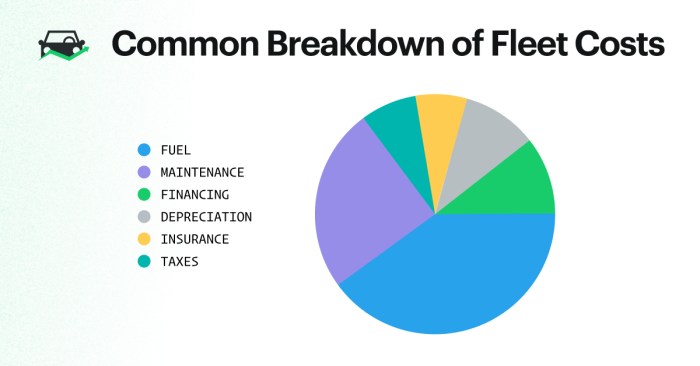

When it comes to comparing fleet maintenance costs, various methodologies are utilized to ensure accurate analysis and decision-making. These methodologies involve different approaches to analyzing cost data and rely on specific tools and technologies to conduct thorough cost analysis for fleets.

Data Collection and Analysis

Data collection is a crucial step in fleet maintenance cost analysis. Fleet managers gather data on maintenance expenses, including labor costs, parts replacement costs, and overall repair expenditures. This data is then analyzed to identify trends, pinpoint areas of high expenditure, and track cost variations over time.

Utilizing fleet maintenance software and management systems plays a significant role in streamlining data collection and analysis processes.

Comparative Analysis

One common approach to fleet maintenance cost analysis is comparative analysis. This involves benchmarking a fleet's maintenance costs against industry standards or similar fleets to evaluate performance and identify cost-saving opportunities. By comparing key metrics such as cost per mile or cost per vehicle, fleet managers can assess their maintenance efficiency and make informed decisions to optimize costs.

Predictive Analytics

Predictive analytics is another methodology used in fleet maintenance cost analysis. By leveraging historical maintenance data and predictive modeling techniques, fleet managers can forecast future maintenance needs, anticipate potential breakdowns, and proactively plan maintenance schedules. This proactive approach helps minimize unexpected costs and downtime, ultimately reducing overall maintenance expenses.

Cost-Benefit Analysis

Cost-benefit analysis is a fundamental methodology in fleet maintenance cost analysis. This approach involves evaluating the costs of maintenance activities against the benefits they bring, such as increased vehicle uptime, improved safety, and extended asset lifespan. By weighing the costs and benefits of different maintenance strategies, fleet managers can make data-driven decisions to optimize their maintenance budget effectively.

Trends in Fleet Maintenance Costs for 2025

As we look ahead to 2025, several trends in fleet maintenance costs are expected to emerge, reshaping the landscape for fleet managers and operators.

Impact of Technology Advancements on Maintenance Costs

Technology advancements, such as predictive maintenance tools and telematics systems, are revolutionizing the way fleet maintenance is conducted. By leveraging data and analytics, fleet managers can now anticipate maintenance needs before they become critical issues, leading to proactive repairs and reduced downtime

This proactive approach not only improves fleet efficiency but also helps in controlling maintenance costs in the long run.

Comparison of Predicted Cost Trends with Historical Data

When comparing the predicted cost trends for 2025 with historical data, we can see a shift towards preventive maintenance strategies and the adoption of innovative technologies. This shift is likely to result in a decrease in reactive maintenance costs and unplanned breakdowns, ultimately leading to a more cost-effective fleet maintenance operation.

By analyzing past trends and incorporating future projections, fleet managers can better forecast their maintenance expenses and allocate resources efficiently.

Factors Affecting Fleet Maintenance Costs

The cost of maintaining a fleet can be influenced by various factors that impact the overall expenses. Understanding these primary factors is crucial for effective cost management.

Vehicle Types and Sizes Impact

The type and size of vehicles in a fleet play a significant role in determining maintenance expenses. Larger vehicles, such as trucks or buses, generally require more frequent maintenance due to their size and complexity. On the other hand, smaller vehicles like sedans or compact cars may have lower maintenance costs.

Additionally, specialized vehicles like refrigerated trucks or construction equipment may have unique maintenance needs that can drive up costs.

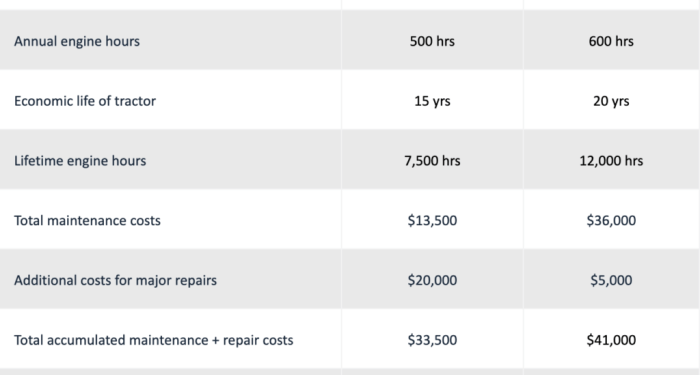

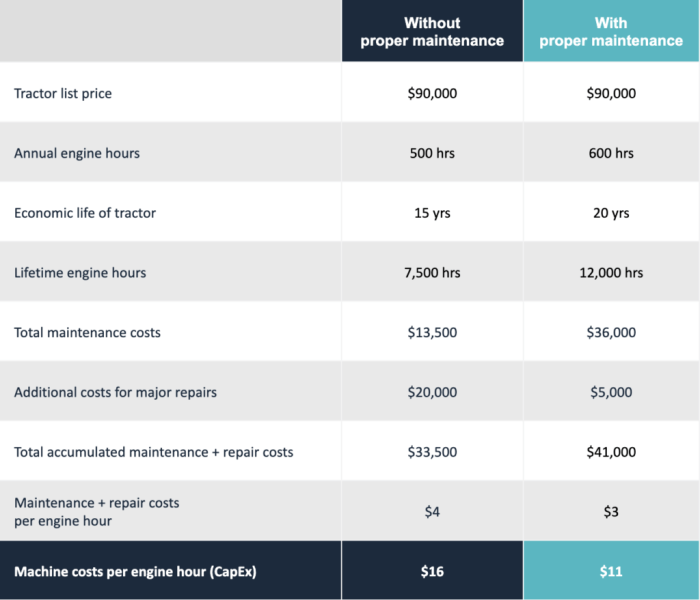

Role of Preventive Maintenance

Implementing a proactive preventive maintenance program can help reduce overall fleet maintenance costs. By regularly servicing vehicles and addressing minor issues before they escalate, fleet managers can avoid costly repairs and downtime. Preventive maintenance can also extend the lifespan of vehicles, leading to long-term cost savings.

Regular inspections, fluid checks, and timely replacements of parts can all contribute to lowering maintenance expenses.

Comparative Analysis of Maintenance Costs Across Industries

When it comes to fleet maintenance costs, different industries have varying expenses associated with keeping their vehicles in top condition. Let's delve into how industries like logistics, transportation, and construction compare in terms of maintenance expenditures.

Logistics Industry

- The logistics industry often has high fleet maintenance costs due to the extensive wear and tear on vehicles from constant use.

- Regular maintenance schedules are crucial in this industry to prevent breakdowns and ensure timely deliveries.

- Specialized vehicles like refrigerated trucks or trailers require additional maintenance, adding to the overall expenses.

Transportation Industry

- In the transportation industry, fleet maintenance costs can vary based on the types of vehicles used, such as buses, taxis, or ride-sharing vehicles.

- Urban transportation fleets may have higher maintenance costs due to stop-and-go driving conditions and frequent starts and stops.

- Regular inspections and part replacements are essential to ensure passenger safety and compliance with regulations.

Construction Industry

- The construction industry often deals with heavy-duty vehicles and equipment, leading to higher maintenance costs compared to other industries.

- Off-road construction vehicles require specialized maintenance due to the rugged terrain they operate in, increasing overall expenses.

- Regular maintenance of construction vehicles is essential to prevent costly downtime and delays in project completion.

Closure

As we conclude our exploration of Fleet Maintenance Cost Comparison: 2025 Edition, we reflect on the insights gained and the importance of staying ahead in managing fleet expenses. Stay tuned for more exciting developments in the world of fleet maintenance costs.

FAQ Summary

What are the key factors influencing fleet maintenance costs?

The primary factors include vehicle types, sizes, and the implementation of preventive maintenance strategies.

How do technology advancements impact maintenance costs for fleets?

Technological advancements can lead to more efficient maintenance processes, potentially reducing overall costs in the long run.

Why is it important to compare fleet maintenance costs in 2025?

Comparing costs helps in identifying cost-saving opportunities, optimizing fleet operations, and staying competitive in the industry.